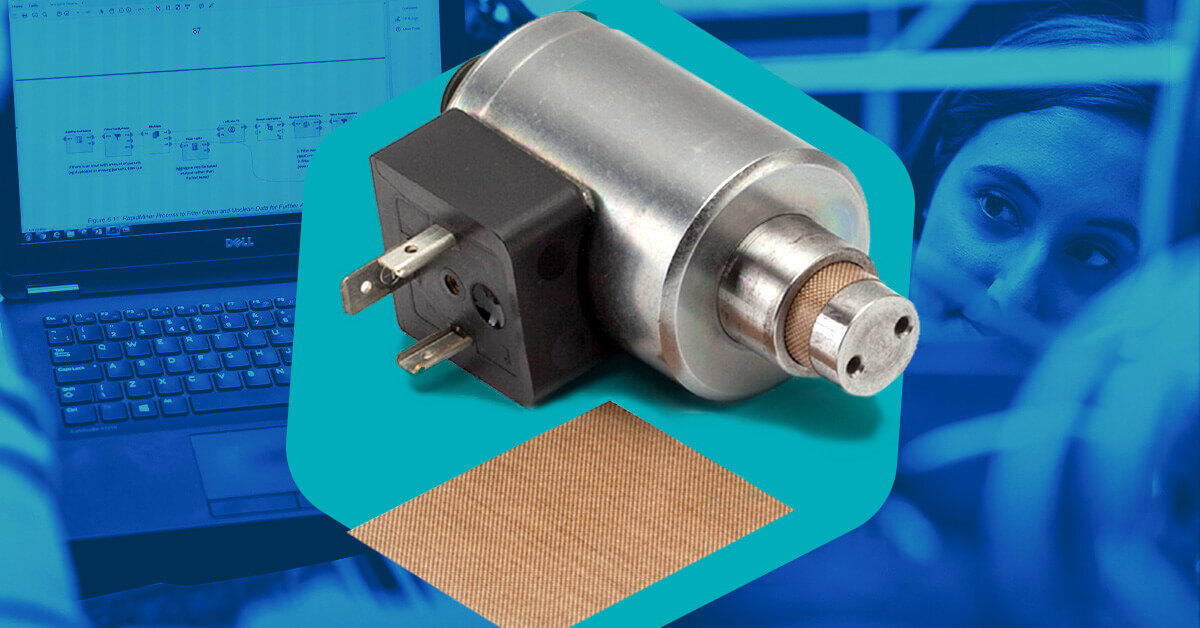

Precision plays a crucial role in developing low friction linings for solenoid and other automotive friction applications.

In the process of producing low friction linings, various materials - e.g. metallic or composite sheets - are converted into by stamping and cutting them into the desired shape and dimensions. The precision of the shape, and the ease with which the lining can be integrated with the armature and the solenoid, is as important as the material itself.

Precision Engineering and Industry 4.0 Integration

To achieve the control in stamping process that ensures consistent and high-quality components, modern converting technologies are now incorporating Industry 4.0 capabilities such as automation and real-time data analytics.

Powered by artificial intelligence, this equipment continuously learns and adapts, autonomously detecting defective parts, optimising sorting processes, and fine-tuning its operations in real-time for peak performance.

This transformative digital technology is integrated in our processes at Versiv. By embracing Industry 4.0, we improve production efficiency and allow for continuous performance monitoring and optimisation of stamping and packing processes of Versiv low-friction linings.

Versiv adheres to IATF 16949 compliant systems, ensuring our products meet stringent quality standards and customer-specific requirements throughout the automotive supply chain.

Customer-Centric Solutions

The Versiv approach centres around partnering with our customers to develop solutions that are unique for them.

Solutions can be tailored to meet specific needs, considering factors such as performance specifications and material properties - ensuring they meet the specific requirements of their applications, from brake systems to transmission control units, and more.

Different materials, which vary in greige options or PTFE content, can be selected based on the desired thickness and lifetime requirements. Further customisation and converting capabilities are also available.

Current Trends in Low Friction Linings

The industry is continuously pushing towards lower friction to improve efficiency and manage thermal performance. Advanced converting technology can address these needs through:

- Comprehensive end-to-end solutions

- Integrated inspection, sorting, stacking, and packing processes

- Enclosed working environments for improved quality control

By focusing on precision engineering, Industry 4.0 integration, and customisation, precision engineering technology continues to advance the development of low friction linings for automotive applications

Versiv Composites provides inspection and sorting, stacking and packing all fully integrated, all within an enclosed environment, or close working cell.

Interested in how Versiv Composites can tailor friction lining solutions for your needs?

Contact us today to learn more