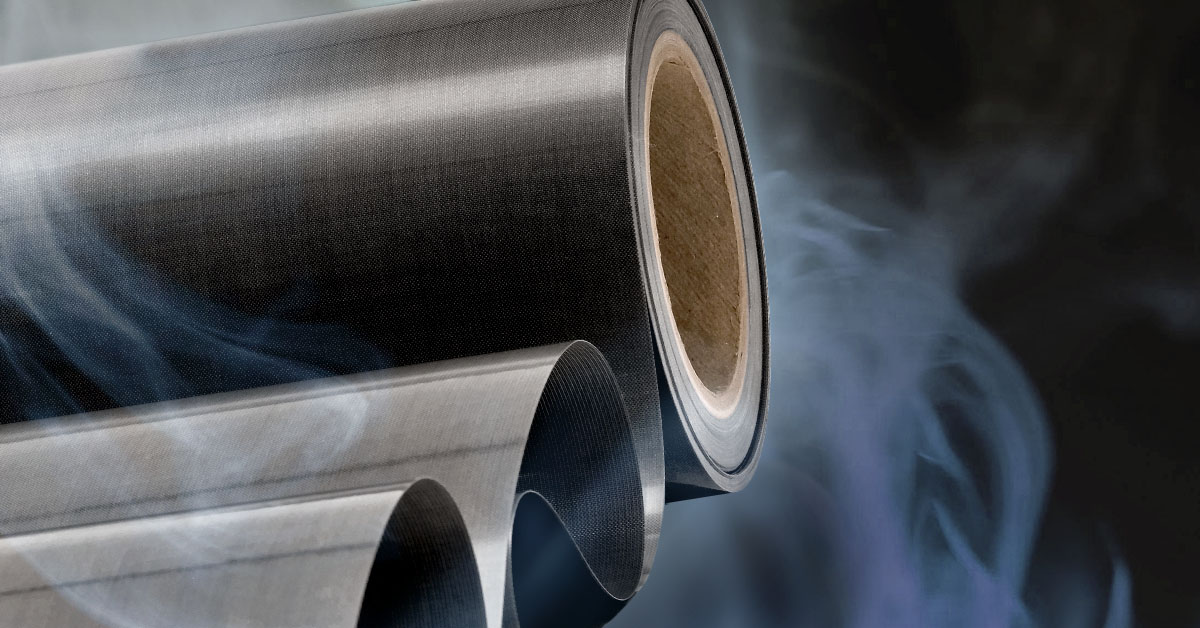

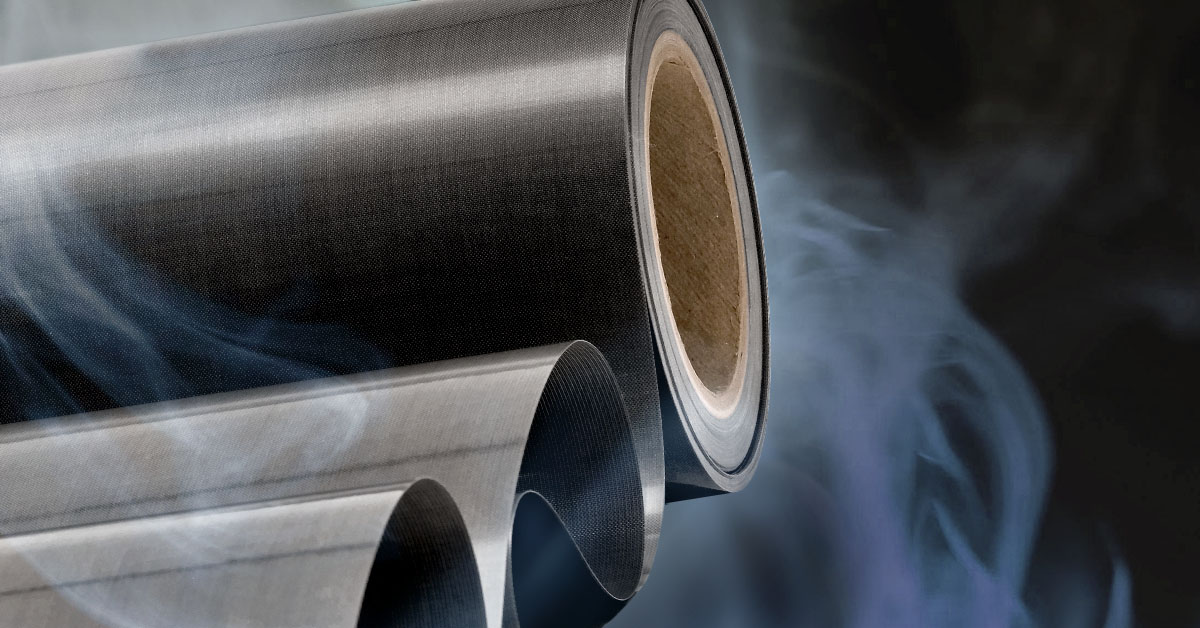

The Power of TCK617 Black

The quest for materials that maintain superior performance, even under the most demanding conditions, is unending for industrial applications.

TCK617 Black is part of the Versiv Coated TCK Aramid range of PTFE-coated fabrics, which provide high tear and tensile resistance, as well as high flexibility, due to the exceptional yield strength, heat resistance and chemical stability from Kevlar® aramid fibers.

TCK617 Black is a high-temperature, one-sided PTFE-coated Kevlar® aramid fiber, specially engineered for the usage in slide bearings. The PTFE coating provides low friction for smooth operation, while the uncoated side allows for the material to be laminated onto metal frames.

The chemical resistance of PTFE ensures high performance and longevity even under harsh conditions, making TCK617 Black of interest for oil and gas industries, as well as mobility applications.

Benefits of TCK617 Black for Slide Bearings

- High temperature load capacity

- Negligible wear for extended service life

- Low friction for smooth operation

- Resistant to dirt and chemicals

- Low static and dynamic fiction factor

- High mechanical stress resistance

Availability and Customisation

TCK617 Black aramid material is available in widths up to 1700 mm, catering to a broad range of applications. Versiv Composites offers custom solutions such as tailoring bearings to any requirement, ensuring the perfect fit for specific applications.

Learn more about our TCK aramid offering

KEVLAR® is a registered trademark of the DuPont Company.