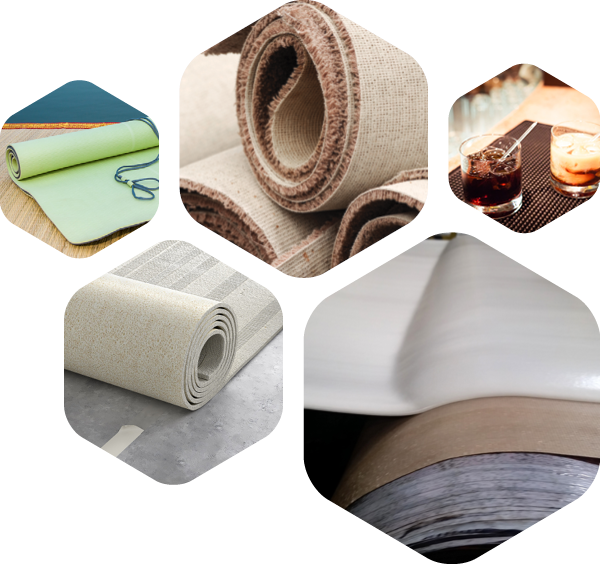

Clean release in cushion backed & padded flooring manufacture

From underlay and carpet backing to anti-fatigue and therapeutic matting, cushioned flooring can be seen across the world in homes, offices, workplaces and public buildings, even on the sports field as artificial turfing backing. Global demand for cushioned flooring has never been higher thanks to its versatility and adaptability of use.

Manufactured in high volume, the process of curing PVC/PU liquid formulation at extreme temperatures is very challenging. Production time can be lost due to the product sticking to the conveyor belt during curing.

Versiv release solutions are used as processing aids, developed to provide high quality products and release downtime under the harsh production environment.

Versiv PTFE-coated belts are non-stick and chemically resistant composites aiding the transport of the formulation as it is metered and processed into the ovens for curing, consistently delivering perfect release in temperatures up to 260°C / 500°F.

Preparation for post- processing where the final product is stripped from the production belt can also be a challenge, with sticking not only ruining the product itself but also contaminating the conveyor. Non-stick and superior release Versiv processing aids are able to deliver hundreds of thousands of metres of product before replacement.