Clean release for rubber flooring mats

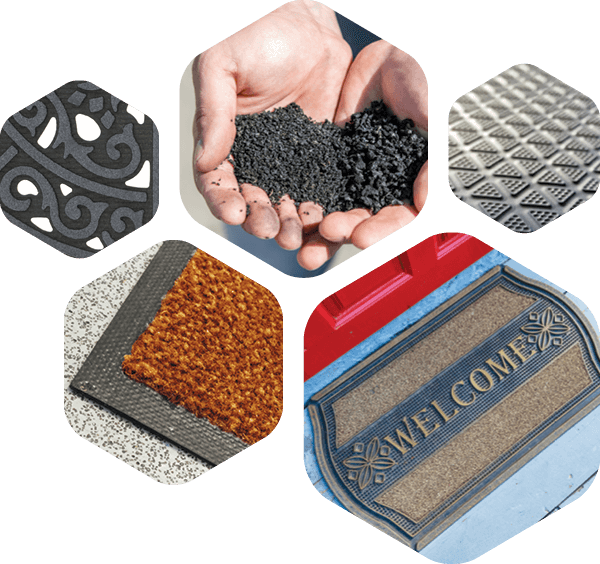

Weatherproof and durable, crumb rubber mats are an increasingly popular choice as exterior high-wear mats: From playgrounds to sports fields, to outside the home or workplace.

High manufacturing volumes, in turn, require continuous manufacturing processes and flexibility in handling chemical additives with a mix of crumb rubber from recycled tires and TPU.

Manufacturing crumb rubber matting is a challenging process that starts with the metering of a recycled crumb rubber and thermoplastic polyurethane mix.

Used to convey the mixture through the oven, Versiv PTFE belts act as a release surface for all the processing stages and well as the transportation of this heavy load. The non-stick and smooth surface guarantees that neither the raw crumb rubber, nor the TPU or molten metered mix can attach to it.

As the metered mixture is conveyed into the heated hydraulic press, it will be subjected to temperatures of up to 200°C / 390°F as it is indexed under pressure. Thanks to their heat transfer properties and mechanical stability, Versiv PTFE-coated belts and press liners aid the application of even pressure and temperature, while their strength and dimensional stability prevents ridging, puckering and creasing. This results in production of a consistently excellent mat.

Clean release means uninterrupted and consistent production with zero unplanned downtime – and your product, with or without the carpet top, delivered flawlessly, and to schedule.