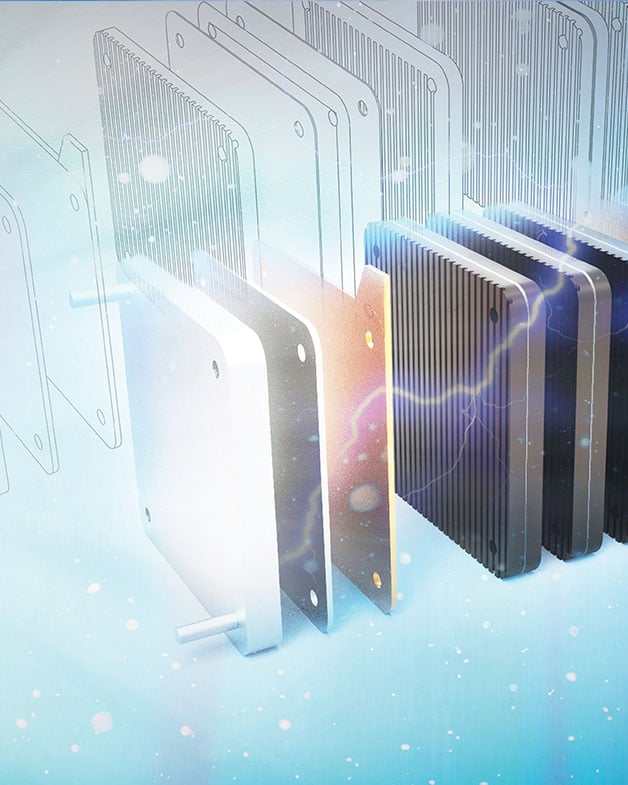

Decal substrates for fuel cell Catalyst Layer production

Versiv materials work as a very precise, smooth and thickness-controlled decal substrate in the production of catalytic layers via decal transfer method. In a second step this substrate becomes a release liner with excellent release properties ensuring that the substrate can be removed without damaging the very costly catalytic layer.

Problems solved:

- Thermal hysteresis

- Non-perfect wetting

- Non-perfect transfer

Applications:

- Processing aids for catalyst coating and lamination of Membrane Electrode Assemblies (MEA)

Versiv Products of Choice for Catalyst Layer Production

Smooth surface and durable release for decal substrates.

Smooth, uniform surface with superior release properties for decal substrates.

Surface allowing wettability and release in combination to strong material properties; low thermal hysteresis.

Please contact us to further discuss your requirements.

Surface allowing wettability and release in combination to exceptional smooth surface and reduced thermal hysteresis.

Features

- Low thickness tolerance

- Excellent non-stick surface

- Excellent dielectric properties

- Superior chemical resistance

- Excellent smooth surface

- Low shrinkage/hysteresis

- Excellent heat transfer

- High temperature resistance up to 260°C / 500°F

Benefits

- Improved productivity due to higher process speed

- Optimal release, allowing both wettability and release

- Low risk of creasing

- Less downtime

- Consistent production processes

- Low risk of failure due to chemical inertness

- Increased cell efficiency by thinner catalyst layers