Friction control and energy saving in printer components

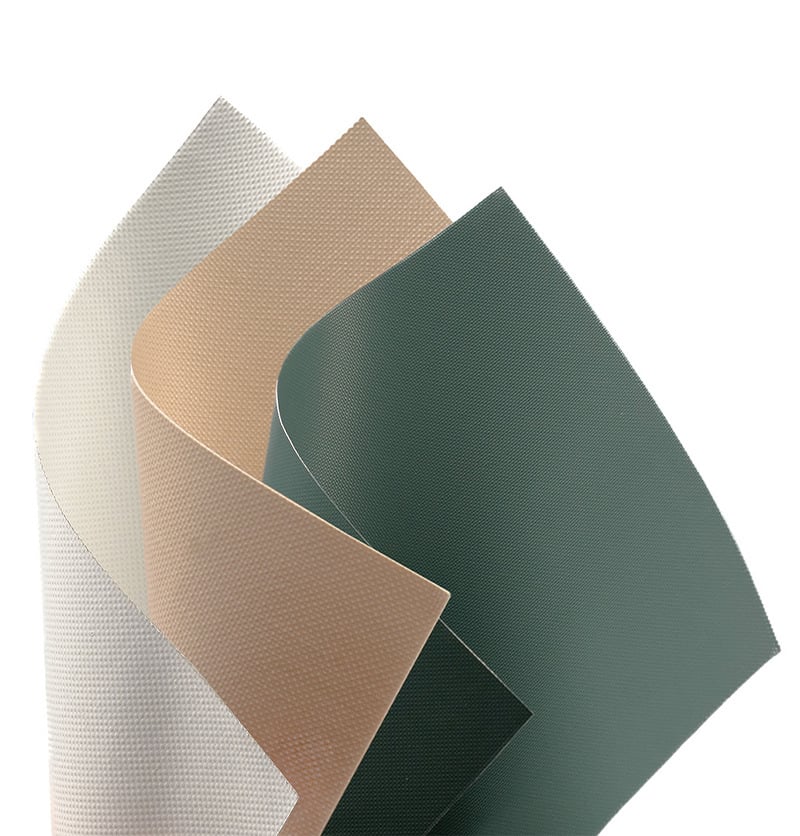

Energy consumption has increasingly become a priority within the electronics' market and reducing power consumption is one of the challenges for design engineers. Used as printer components, Versiv low friction linings act as a linear glide bearing within high speed, high productivity printers.

Versiv components provide significant advantages by reducing the friction and power needed to move the paper sheets over the ink-fusing zone over many thousands of cycles. Frictional properties are optimised by engineering surface characteristics to ensure the lowest coefficient of friction and an easy slide surface.

In addition to compatibility with any lubricants on the machine, the temperature resistance and stability of the PTFE lining is critical and means that wear properties remain consistent even at elevated temperatures (up to 356°F / 180°C).

Given the industrial scale of use, reliable wear resistance and long-term performance over millions of cycles are essential, which is why Versiv Low Friction Linings are the preferred choice in demanding applications.