Versiv Manufacturing Aids for Thermal Lamination

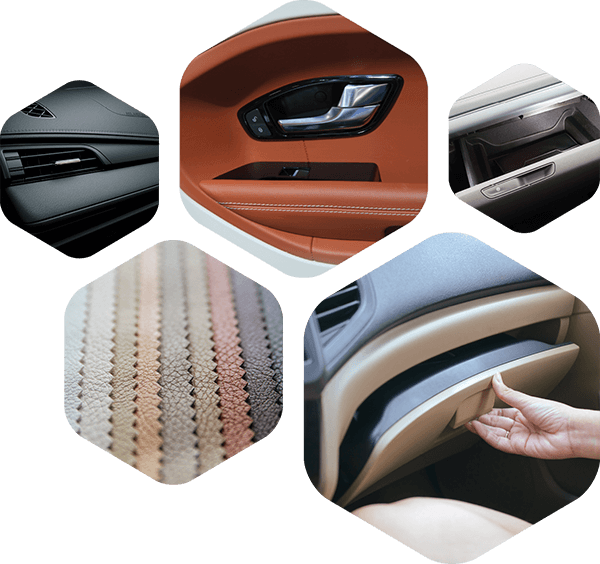

Thermal lamination is a highly versatile process used to produce a variety of lightweight interior car components. The high-volume production of organo sheets and décor materials requires flexibility in handling different substrates, making Versiv processing aids essential for seamless lamination operations.

Versiv PTFE-coated fabrics, utilised as release sheets and conveyor belts, exhibit excellent temperature and abrasion resistance. Compatible with nearly all types of substrates and adhesives used, Versiv release solutions maximise the output and machine productivity. One of the main challenges in this process is preventing line stoppages and downtime caused by cleaning residue from molten resins. Versiv's products ensure uninterrupted workflow, significantly reducing the risk of defects and yield losses.

During the thermal lamination process, different products, such as substrates, décor materials, molten polymers and adhesives are combined in-line to produce a component part.

In this aggressive and sticky environment, Versiv release solutions are used as conveyor belts that carry the heavy load at high-speed and high temperatures.

The non-stick PTFE surface ensures that the final product – either organo sheet or décor material – releases perfectly from the belt. Defect free and smooth, Versiv coated fabrics offer long lasting release and minimizs the risk of unplanned downtime when residue from a previous batch requires a clean-up.