Microwave Transmissible Fabrics

- Band-agnostic up to 100GHz

- Permanent hydrophobicity

- Strong and flexible composites

- Excellent thermal dissipation and heat management

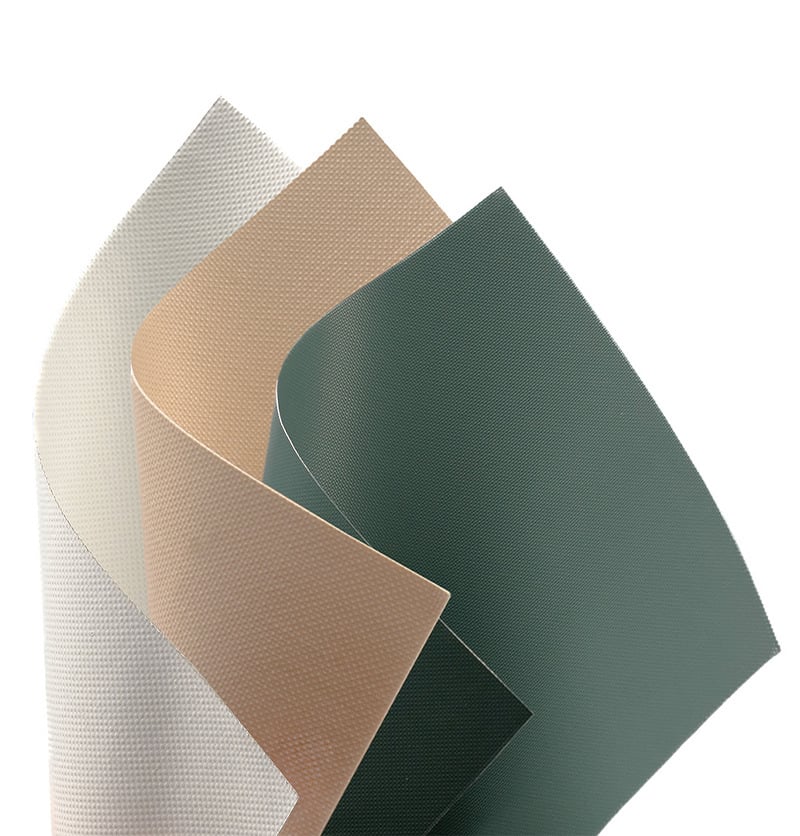

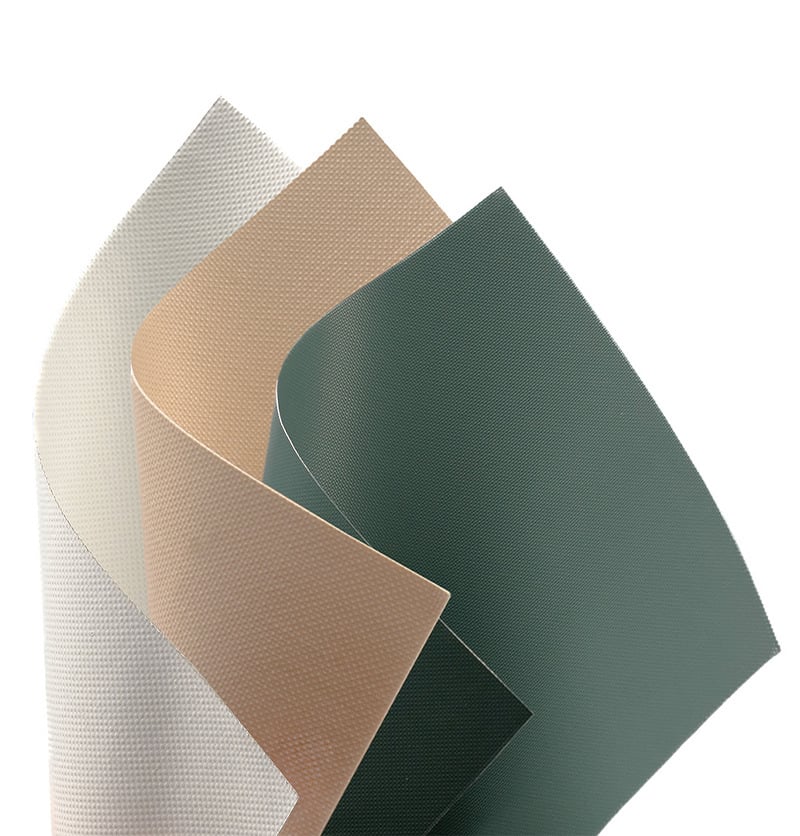

- Various colours available

· Band agnostic up to 100GHz

· Strong and flexible composites

· Various designs, colours available

· Permanent hydrophobicity

· Excellent thermal dissipation and heat management

Band-agnostic simply means that the radome or antenna cover does not need tuning for the frequency of the incident signal.

Versiv Microwave Transmissible Fabrics are band-agnostic and mechanically strong enough to provide the required structural integrity at an extremely low thickness (typically around 0.2mm / 8 mil) – up to 5X thinner than typical concealment solutions.

By keeping this minimal thickness in front of the array, the fabric’s thickness remains small enough compared to the signal’s wavelength to not induce excess loss or scattering, and so provides optimum performance at any operating frequency regardless of band, indigence angle, carrier frequency or future innovations.

The fifth generation of cellular network functionality needed to meet the growing demand for connected devices and associated data requires robust infrastructure to support it. At its core, 5G intends to do four things:

The infrastructure required for a 5G network will be gradually implemented and evolve from what is currently in place. 5G is being deployed across three frequency bands:

FTMS 191A-5041

FTMS 191A-5030

FTMS 191A-5102

FTMS 191A-5136

ASTM D149-81